FEATURES/ BENEFITS

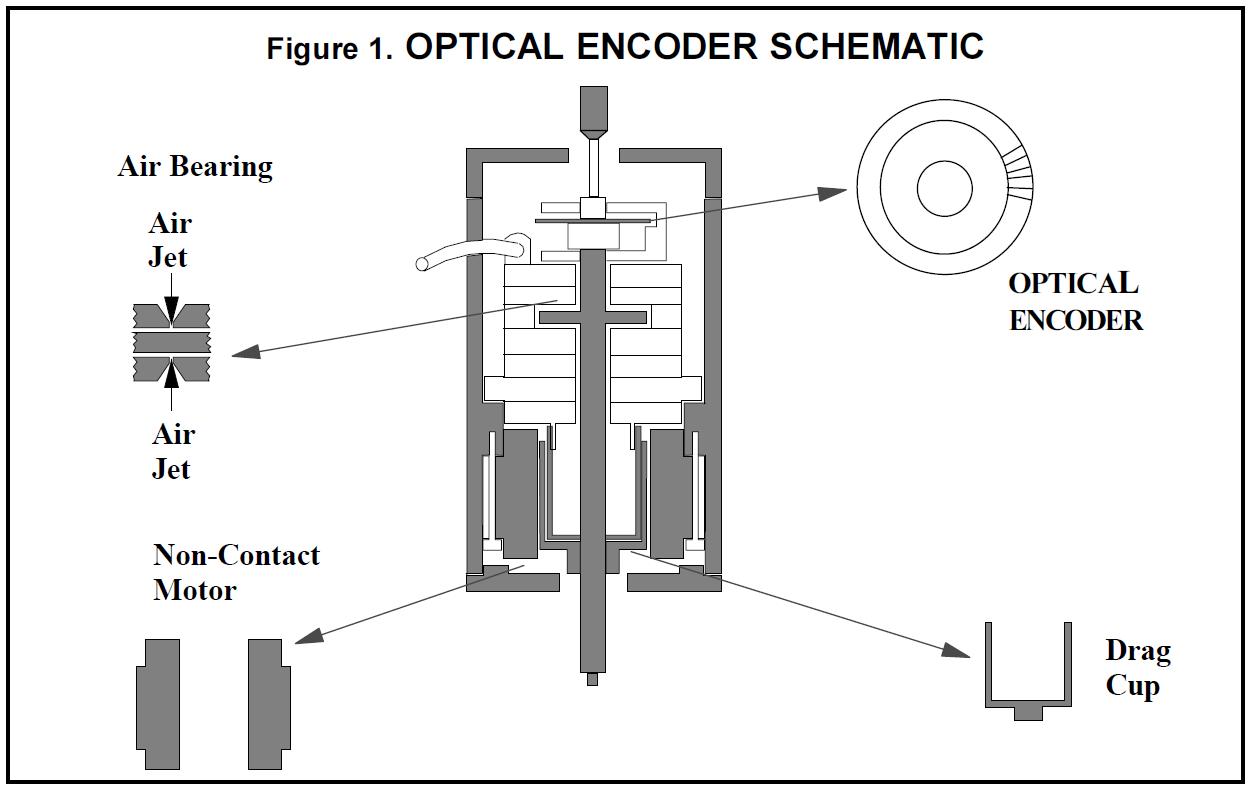

Controlled stress rheology has become the most popular approach for making rheological measurements for a variety of reasons including the ability to nondestructively probe the structure of delicate materials such as colloids and dispersions. The ability to evaluate these difficult-to-measure materials is directly dependent on the rheometers ability to reproducibly apply small stresses and to detect the small responses produced by those stresses. The former capability is determined by the characteristics of the rheometer torque motor and associated electronics. (The TA Instruments CSL2 50 is the best unit if this is the major consideration.) The latter capability is determined by the rheometer displacement measuring sensor. The high resolution optical encoder of the CSL2 provides excellent displacement (strain) resolution (2.5 mradians) which is adequate for even the most demanding material evaluations. This capability is beneficial in flow (where lower shear rates can be measured), creep (where smaller strains allow the linear portion of the curve to be detected more quickly), and oscillation (where smaller strains allow materials with very small linear viscoelastic regions to be more accurately evaluated and more frequencies to be used in multiwave oscillation without exceeding the materials linear limits).

SPECIFICS

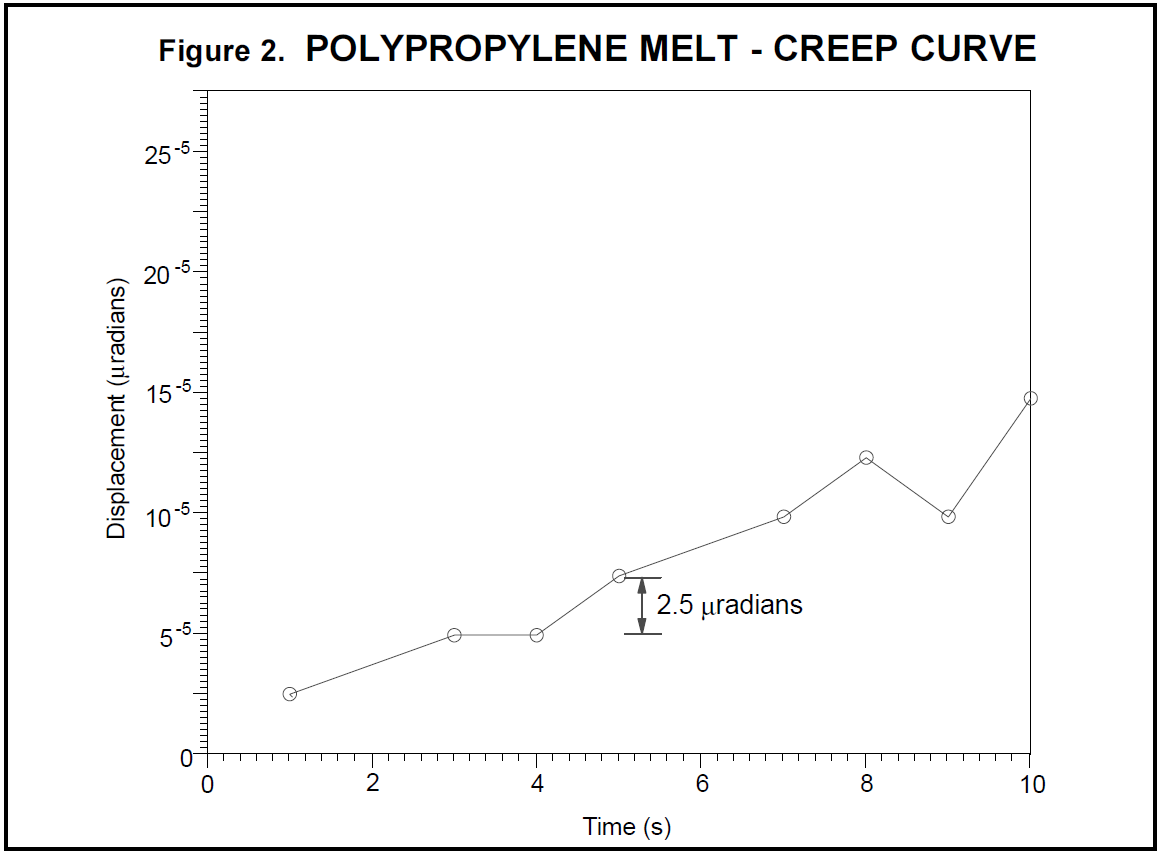

In controlled stress rheometers the angular deflection under a controlled stress is the measured dependent variable. To be able to evaluate the widest range of materials, an optical encoder system to measure this angular deflection is ideal. It is able to detect movements as small as 2.5 mradians and angular velocities up to 50 radians/second. An optical encoder (Figure 1) is generally used since it is accurate, mechanically simple, and relatively low cost. In addition, an optical encoder needs no calibration, being an absolute measure of angular movement as well as being free from the drift present in analogue displacement measuring systems. Furthermore, an optical encoder can measure a wide dynamic range of displacement. Hence, the TA Instruments CSL2 incorporates a high quality optical encoder.

Figure 2 shows a typical application where high strain resolution is important. Creep tests are often used to quantify the low shear rate (Newtonian plateau) viscosity because this value is representative of the materials molecular weight. The further this creep measurement can be extended to approximate low shear rates (small displacements), the more confidence that can be ascribed to correlation with molecular weight.